Kegerator Coupler Parts: Essential Accessories for Your Home Keg

Curious why your draft beer ends up too foamy or disappointingly flat? The secret lies in the small but mighty components connecting your keg to the tap. Without the right setup, even the best brew can lose its crisp taste and perfect carbonation.

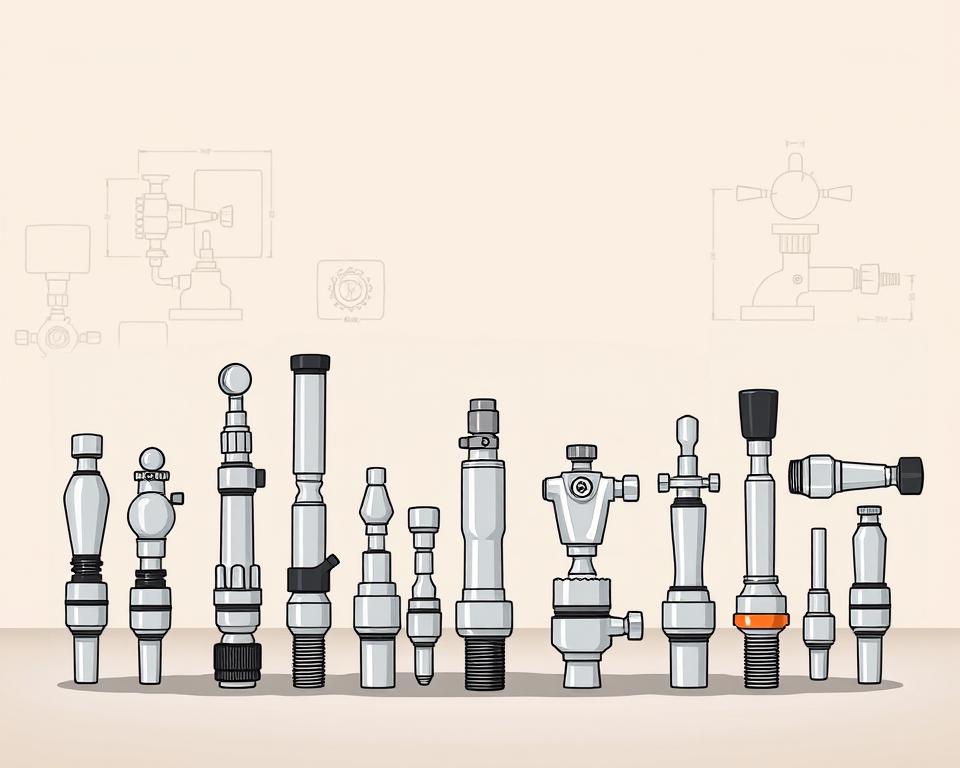

At Installation Parts Supply, we know that a smooth pour starts with quality hardware. No matter if you brew at home or simply enjoy draft beer, knowing these beer keg parts diagram parts makes all the difference.

Every part—from the washers to the gas lines—matters for keeping the right pressure and taste. Over 90% of dispensing issues trace back to worn or mismatched components. With a bit of know-how, you can keep your setup working without a hitch.

Major Highlights

- Proper coupler selection ensures optimal beer flow and flavor.

- Installation Parts Supply provides reliable plumbing solutions for draft systems.

- Regular maintenance prevents common pouring problems.

- Different beer types may require specific coupler styles.

- Most system failures originate from coupler-related issues.

Define the Kegerator Coupler

The perfect draft beer starts with the right connection between your keg and tap. Think of the keg coupler as the connector between your CO₂ cylinder or nitrogen tank and the beer line, employing pressurized gas to deliver beer flawlessly to your taps. Consider it the powerhouse of your draft beer system—remove it, and the flow stops.

That tiny gadget serves a dual purpose: gas delivery to pressurize and valve control to pour your beer. Its interior consists of a probe, a check valve, and distinct ports for beer and gas. Together, they keep your beer fizzy and antifoam.

| Part | Role | Frequent Problems |

|---|---|---|

| Coupler Probe | Punctures the keg seal | Misalignment causes leaks |

| Check Valve | Prevents backflow | Worn valves lead to flat beer |

| Gas/Liquid Ports | Connects to lines | Foaming from loose connections |

Seventy-five percent of newcomers misattach the coupler, causing issues. That leads to foam floods, leaks, and ruined beer. Check Installation Parts Supply’s charts and videos for correct setup.

Universal designs mean most couplers work similarly, but always match yours to your keg type. Using the wrong coupler can harm both your pour and your gear.

Types of Keg Couplers and Their Uses

Not all keg connections are created equal—some are designed for specific brews. Matching the right coupler to your beer ensures optimal carbonation and flavor. Here’s how to pick the perfect fit.

Standard D System Coupler

It’s used by roughly 85% of U.S. craft breweries. That valve locks onto domestic kegs with ease. Pro tip: Look for the Sankey name stamped on the side.

U System Coupler

Stamped with a harp mark, it’s essential for nitro-charged stouts. A 75% nitrogen mix gives you that signature creamy foam. A U coupler will not seat on a D-type keg—don’t attempt it.

Reverse-Thread S System Coupler

Heineken and other European imports need this reverse-thread version. The left-hand twist prevents mix-ups with D Systems. It’s roughly an inch taller than the U.S. version.

A-, G-, and M-Type Couplers

UK/German imports call for these unique couplers:

- A System: Fits Paulaner and Warsteiner kegs perfectly. Its sliding latch design is fail-safe.

- G System: Fits Bass and Boddingtons with its tri-flat stem. A pub staple across the UK.

- M-Type Coupler: Secures Schneider Weisse barrels. You’ll hear a click once it’s set.

Their guide highlights D in green, U in black, S in blue. One Midwestern brewery cut costs by $3K annually with the right couplers. Always favor exact compatibility over “universal” marketing.

Key Coupler Components Explained

That perfect pour depends on finely tuned parts. Together, they keep carbonation in and foam out. Let’s break down the key hardware that keeps your system running.

Probe + Return Valve

A stainless probe punctures the seal to regulate flow. Premium models last 3x longer than economy versions. Underneath, the check valve stops reverse flow—our top replacement item.

Nut and Washer Assembly

Your seal depends on that hex nut. Brass is economical; stainless fights rust. Use nitrile washers in the cold—EPDM fails below 40°F.

| Component | Construction | Key Benefit |

|---|---|---|

| Coupler Probe | Stainless Steel | Long-lasting |

| Check Valve | FDA-approved plastic | Prevents flat beer |

| Coupler Nut | Brass/Stainless | Cost-effective & durable |

Pressure Ports

The gas port handles 20–30 PSI for CO₂ or nitrogen. Incorrect pressure spells foam issues. Stick to 3/16″ ID beer lines for smooth pours. Rebuild kits with FDA seals simplify maintenance.

Pro Tip: Change seals twice a year or per 50 kegs. A $3 washer replacement beats a $150 coupler failure.

How to Set Up Your Kegerator Coupler

Getting your draft system right means perfect pours every time. Proper installation prevents foam, leaks, and flat beer. Use this step-by-step for a seamless install.

Connecting the Coupler to the Keg

Lift the handle and align the coupler’s lugs with the keg’s slots. Rotate until secure but don’t overtighten. Slim models save 4–5″ of headroom.

Installation Parts Supply’s torque wrench ensures hex nuts are secured at 8–10 ft-lbs. Eighty percent of leaks stem from a crooked probe. Never reuse old washers.

Attaching Gas and Beer Lines

Connect the gas hose to the coupler’s port using 5/16″ MFL fittings. Apply thread sealant to prevent CO₂ leaks. Use 10-12′ of 3/16″ tubing to balance draft pressure.

| Task | Equipment | Note |

|---|---|---|

| Gas Line | Thread sealant | Test at 30 PSI for bubbles |

| Beer Line | Pipe cutter | Cut straight for proper seals |

| Leak Test | Leak detector | Monitor for a full day |

Advanced systems integrate mobile apps for real-time pressure monitoring. Our quick-connects helped a Denver bar slash foam by forty percent. Stop the CO₂ at the source for serious leaks.

Coupler Troubleshooting

A foam burst spoils your draft faster than anything. Most pouring problems stem from simple fixes once you know where to look. Let’s tackle the frequent headaches and their solutions.

Leaks and Foamy Beer

Sixty-eight percent of draft issues are foam-related. Start by checking your temperature—ideally 38°F for most ales. Warm beer releases CO₂ prematurely.

Next, inspect your beer line connections. Soap test any fitting—bubbles point to leaks. Tighten any loose fittings with a wrench, but don’t over-tighten.

- Check ball can lead to uneven pours and audible leaks

- Not sure on PSI? Use this guide:

| Beer Type | CO₂ PSI | N₂ Ratio |

|---|---|---|

| Lagers | 10–12 | N/A |

| Stouts | 25–30 | 75% nitrogen |

Coupler Fit Problems

Loose couplers almost always trace back to worn seals. Installation Parts Supply reports this fixes 40% of attachment issues. If the face is warped, swap the entire coupler.

Use plastic shims to level off rough keg tops. They’re a cheap way to stop wobble. Low-profile models solve clearance problems in compact coolers.

Pro Tip: Keep a five-seal washer kit on hand for emergencies. A Chicago bar cut waste by 18% after training staff on these quick fixes.

Remember—frost on your CO₂ tank signals overuse. Allow the tank to warm up prior to any valve tweaks. Recalibrate digital gauges every year.

Maintenance for Your Coupler

Hygienic systems yield the best flavor. Leftover yeast and oils harm both taste and pouring. Regular care preserves performance.

Disassembly and Soaking

Begin with a full teardown. Separate the handle, probe, and check valve. Soak everything in a PBW bath (1 oz per gallon) for about 15–20 minutes. It dissolves yeast and hop deposits.

Use our brush kit to clean narrow passages. Focus on the ball valve—gunk loves to hide there. Flush well to prevent soap residue.

Best Coupler Cleaners

PBW leads the pack for balanced cleaning. Acid cleaners work faster but can damage rubber over time. For commercial setups, ultrasonic systems blast away debris with sound waves.

- Air Drying: Blow dry or wipe with a microfiber towel.

- Sanitizing: Meet FDA CFR 117: 30 seconds to sanitize.

- Logs: Maintain a cleaning log for consistency.

UV sanitation guards seals longer. Dispose of alkaline wash properly to protect drains. A little effort ensures quality pours and extends your system’s life.

In Closing

Enjoy crisp, fresh beer by mastering your draft beer system. Choose compatible parts, maintain them well, and install correctly. Installation Parts Supply offers lifetime support and seasonal discounts on rebuild kits to keep your pours perfect.

Regular upkeep can stretch your hardware lifespan by seven years. Grab the free compatibility guide or sign up for a pro webinar. One yearly inspection prevents headaches—our long-term customers agree.

Time to level up: head to Installation Parts Supply and improve your home bar.